After an intense three-phase pilot scale test program, Keliber was delighted to discover a battery-grade lithium hydroxide. This was done in conjunction with FLSmidth and resulted in a 96.3% conversion rate which is high as it was done in a high-temperature pilot trial.

The test sought to study how Rapasaari’s ore behaved in all its processes up to the last stage of the resulting product which is lithium hydroxide. Previous pilot tests have been performed, with the main one done on SYVAJARVI’S ore, where the first phases of mining start.

The pilot test began in the autumn of 2021 where a sample of 130 tones from the Rapasaari deposit was studied. The ore was mined through drilling where diamond core and percussion methods were applied at the site.

The second phase involved testing mineral processing at GTK Mintec’s Pilot Plant in Outokumpu. The study concentrated on the critical mineral processing stages which are grinding, classification, crushing, flotation, dewatering, and magnetic separation.

The third stage of the pilot study involved a rigorous process in the rotary kiln of converting alpha spodumene into beta spodumene under high temperatures. This process was capable of accomplishing a conversion rate of 96.3%. At this particular stage, FLSmidth collaboration took place.

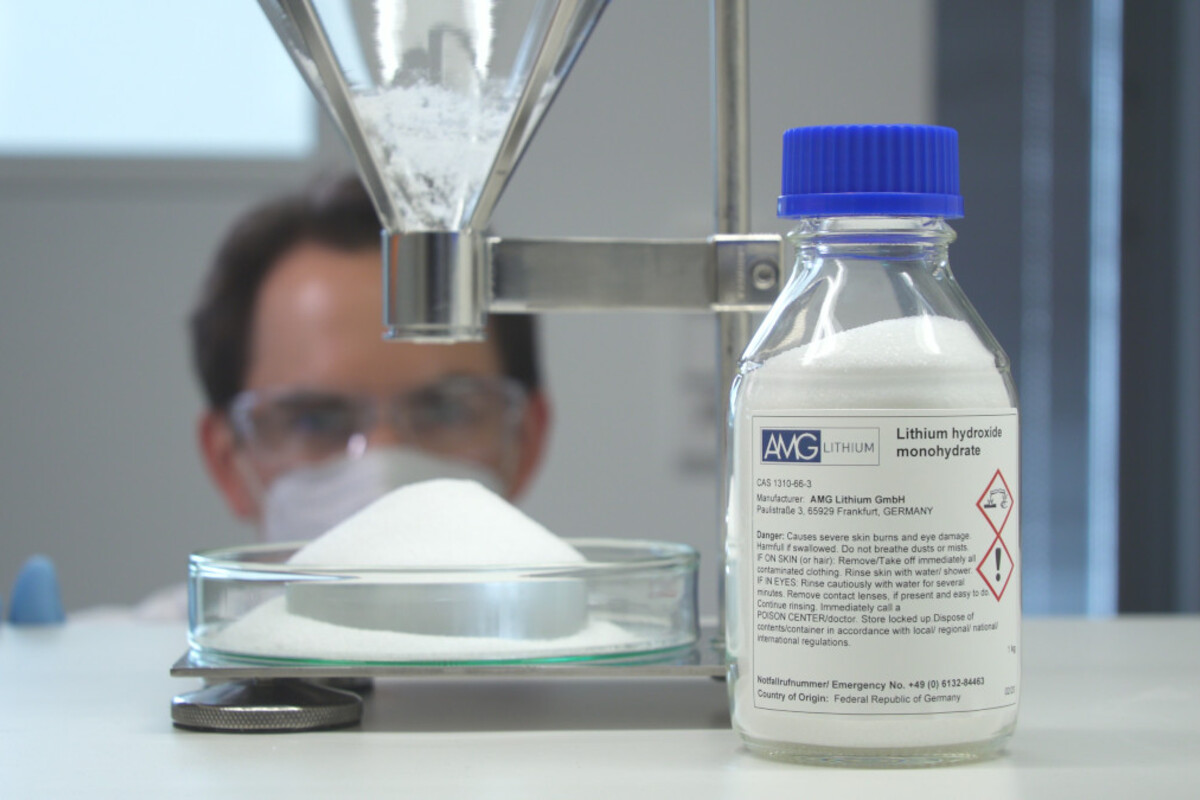

The fourth stage of the pilot study has not yet been announced by Keliber. It is the final stage that involves the production of battery-grade lithium hydroxide monohydrate through a leaching process of soda. The announcement of the results is expected to begin in the following weeks.

It should be noted with great concern that this pilot study will be a critical asset in the energy industry since it will guide other innovation projects that will happen in the future.

The collaboration of FLSmidth is also a critical lesson to learn that indeed one sector needs the other if innovation of high-quality process is anything to go by.